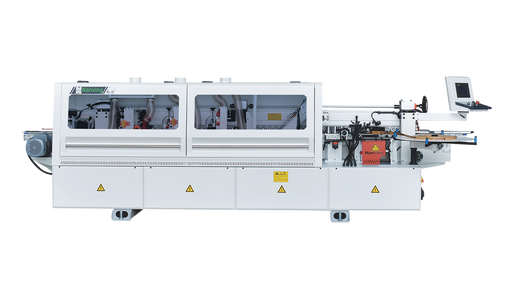

An edgebander is a vital piece of machinery in the manufacturing and woodworking industries, designed to enhance the aesthetics, durability, and functionality of various products. So, what does an edgebander do, and why is it so essential?

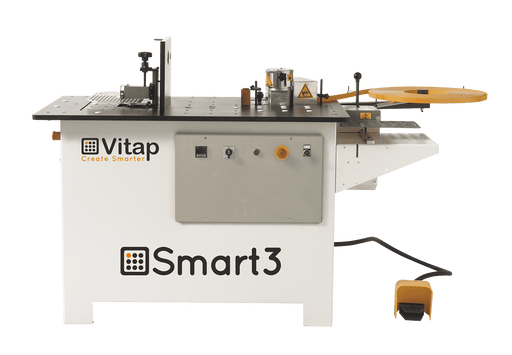

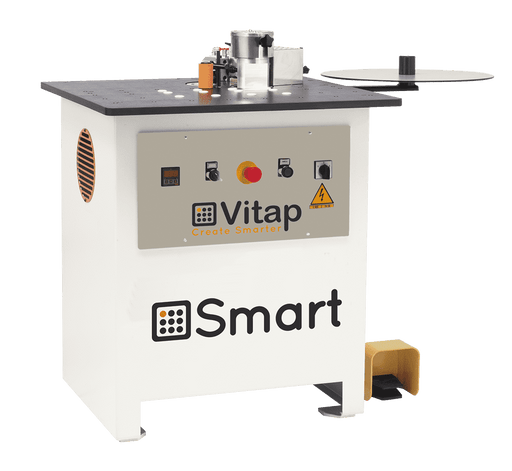

In essence, an edgebander is a specialized machine that applies a band or strip of material (usually PVC, ABS, wood veneer, or acrylic) to the edges of panel materials, such as particleboard or MDF. This banding material not only conceals the exposed and vulnerable edges of these panels but also serves to improve their overall appearance and strength.

The primary functions of an edgebander include:

- Edge Banding: The core function of an edgebander is to apply edge banding material to the edges of panels. This can be solid wood, PVC, or other materials, depending on the desired finish. The edgebander expertly attaches this material, ensuring a seamless and uniform appearance.

- Trimming: After the banding material is applied, an edgebander typically trims any excess material, ensuring that the edges are perfectly flush and smooth. This step is crucial for achieving a professional and polished look.

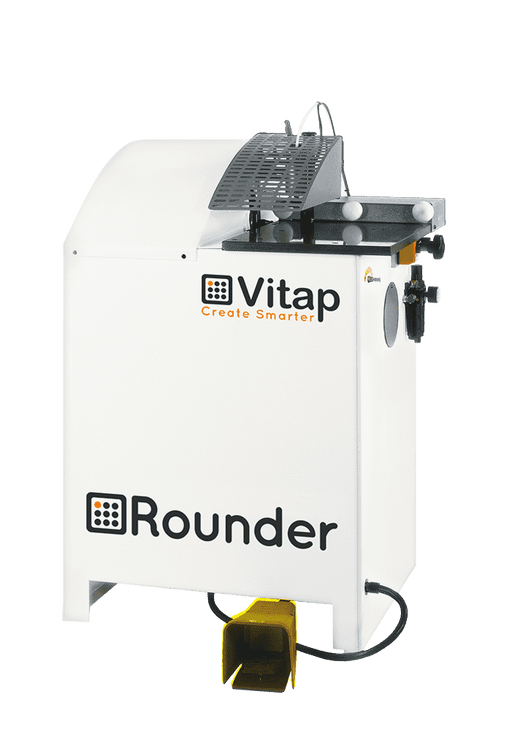

- Edge Finishing: Edgebanders may also include functions for rounding, beveling, or adding various profiles to the edges. This enhances the aesthetics of the finished product and reduces the risk of injuries from sharp edges.

- Gluing and Heat Activation: Some edgebanders use adhesive to attach the banding material, and then heat is applied to activate the glue. This ensures a strong bond between the banding and the panel material.

The applications of edgebanders are incredibly diverse and encompass a wide range of industries, including furniture manufacturing, cabinet making, architectural millwork, and interior design. Whether you're producing custom furniture, kitchen cabinets, or decorative wall panels, an edgebander plays a crucial role in achieving a polished and professional finish.

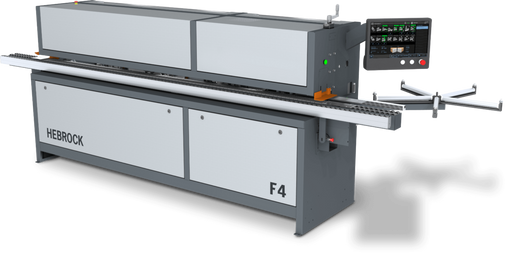

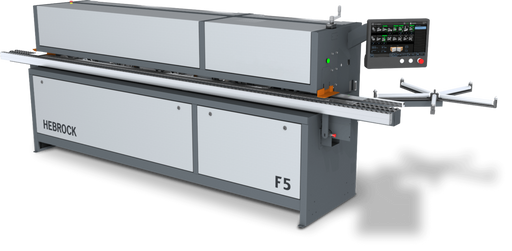

Key Features of Industrial Edgebanders:

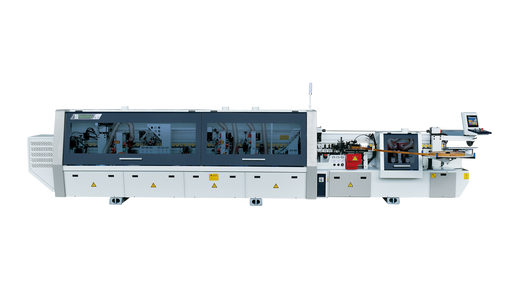

Industrial edgebanders are sophisticated machines that bring efficiency and precision to the woodworking and manufacturing industries. They offer several key features that make them invaluable in the production process:

- Precision Edging: Industrial edgebanders apply edge banding material with remarkable precision, ensuring a clean and uniform finish on workpieces.

- Material Compatibility: These machines are versatile, accommodating a variety of edge banding materials, including PVC, ABS, wood veneer, and acrylic.

- Automatic Trimming: Edgebanders typically include automatic trimming functions, ensuring that the edges are perfectly flush and smooth.

- Edge Finishing Options: Some machines offer edge finishing capabilities, such as rounding, beveling, or adding profiles, enhancing the aesthetics of the final product.

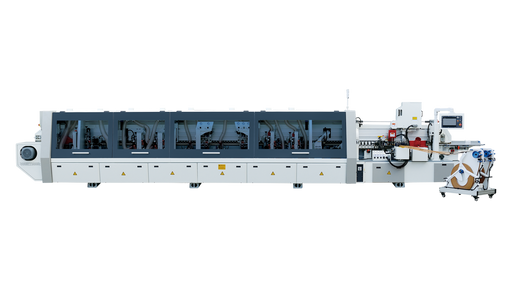

- Efficiency and Speed: Industrial edgebanders streamline the edge banding process, significantly reducing production time and labor costs.

Applications of Industrial Edgebanders:

Industrial edgebanders find applications in a wide range of manufacturing processes, including:

- Furniture Manufacturing: Edgebanders are essential in producing furniture with flawless, edge-banded components, providing a clean and professional appearance.

- Cabinet Making: They are crucial for crafting seamless, edge-banded cabinet parts, ensuring the longevity and aesthetics of cabinets.

- Panel Processing: Industrial edgebanders expedite the production of panels used in cabinetry, shelving, and interior fixtures, creating a finished look.

- Architectural Millwork: Edgebanders enhance the quality and durability of architectural millwork components, such as moldings, casings, and trim.

Benefits of Using Industrial Edgebanders:

Utilizing industrial edgebanders offers numerous advantages for manufacturers:

- Flawless Finish: Edgebanders guarantee consistent and impeccable edge banding results, eliminating manual errors.

- Efficiency and Productivity: These machines automate the edge banding process, saving both time and labor costs while reducing the risk of inconsistencies.

- Enhanced Aesthetics: Edgebanders create a clean and professional finish, enhancing the visual appeal of products and reducing the need for additional finishing work.

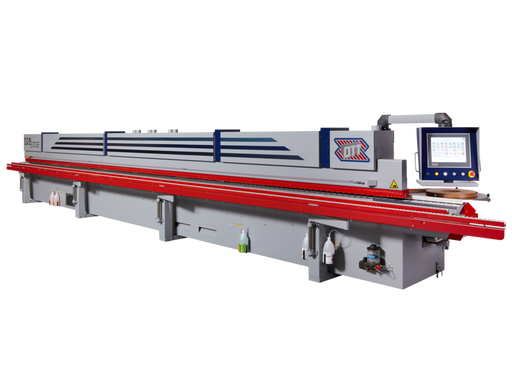

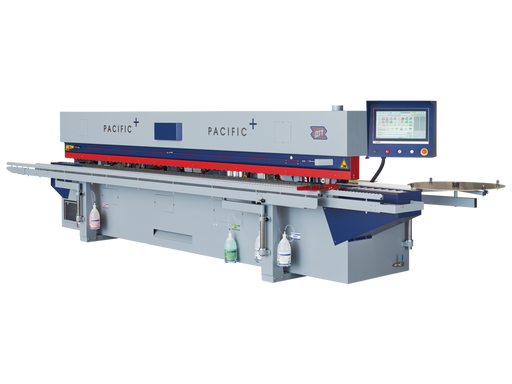

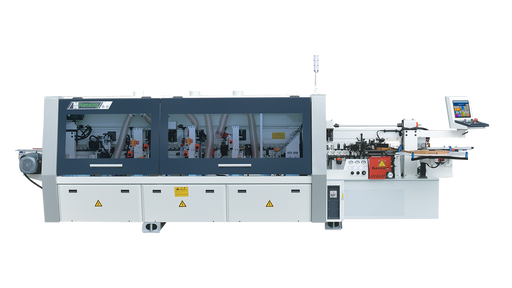

Choosing the Right Industrial Edgebander:

Selecting the ideal industrial edgebander is a critical decision for manufacturers. Consider the following factors when making your choice:

- Edging Width: Ensure that the machine can accommodate the width of the edge banding material required for your specific applications.

- Material Compatibility: Verify that the edgebander can handle the materials you work with, such as wood veneer or PVC.

- Production Volume: Choose a machine that aligns with your production volume. Smaller-scale manufacturers may opt for compact models, while larger operations require high-capacity machines.