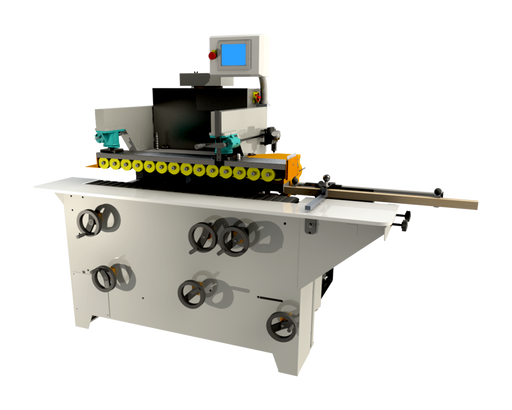

A Shape and Sand Machine is a versatile and indispensable woodworking tool used in various applications, particularly in the manufacturing of furniture, cabinets, and architectural millwork. What makes these machines essential is their ability to shape and sand woodwork components with precision and efficiency.

Shape and Sand Machines perform two primary functions. First, they shape the wood, creating intricate designs, profiles, and moldings. This shaping process allows woodworkers to craft precise and unique components, from table legs to decorative moldings, adding a touch of elegance to their creations.

The second function is sanding. After shaping, these machines meticulously sand the wood surfaces, ensuring a smooth, uniform finish. This critical step prepares the wood for further finishing or assembly, significantly reducing manual labor and time while maintaining the desired quality.

What sets Shape and Sand Machines apart is their versatility and the ability to customize workpieces. Woodworkers can create a wide range of profiles and moldings, meeting the unique requirements of each project or client's specific preferences. Overall, Shape and Sand Machines play a pivotal role in achieving consistent, high-quality woodworking products and optimizing production efficiency in the industry.

Key Features of Shape & Sand Machines:

Shape & Sand machines offer a range of key features that make them indispensable in woodworking operations:

- Precise Shaping: These machines can expertly shape workpieces, including intricate designs, moldings, and profiles, with exceptional precision.

- Sanding Capabilities: In addition to shaping, Shape & Sand machines integrate sanding functions to ensure a smooth and finished surface, ready for further finishing or assembly.

- Versatile Workpieces: They are suitable for a variety of workpiece sizes, allowing flexibility in woodworking projects.

- Automation Options: Some advanced models offer automation features, enhancing production efficiency.

Applications of Shape & Sand Machines:

Shape & Sand machines find applications across multiple woodworking sectors:

- Furniture Manufacturing: In the production of high-quality furniture, these machines are instrumental in creating shaped and sanded components, such as table legs, chair arms, and decorative moldings.

- Cabinet Making: Cabinet makers utilize Shape & Sand machines to craft intricate cabinet doors, drawer fronts, and panel profiles, ensuring a perfect fit and finish.

- Architectural Millwork: For architectural millwork applications, these machines create decorative moldings, casings, and customized profiles that enhance the aesthetic appeal of interior spaces.

Benefits of Using Shape & Sand Machines:

The advantages of incorporating Shape & Sand machines into woodworking processes are substantial:

- Precision and Quality: These machines ensure that shaped and sanded components meet exact specifications, resulting in consistent, high-quality woodwork pieces.

- Time Efficiency: By combining shaping and sanding functions, they significantly reduce the labor and time required for each workpiece, leading to improved production efficiency.

- Customization: Shape & Sand machines offer the flexibility to customize workpieces, enabling woodworkers to meet unique project requirements and client preferences.

Choosing the Right Shape & Sand Machine:

Selecting the appropriate Shape & Sand machine is a critical decision for optimizing woodworking operations. Consider the following factors:

- Shaping Capabilities: Determine the machine's shaping capabilities, including the range of profiles, molding, and detailing it can produce.

- Sanding Functions: Evaluate the sanding functions, as they should align with your requirements for a smooth, finished surface.

- Automation Features: Some Shape & Sand machines provide automated features, improving efficiency and reducing manual labor.