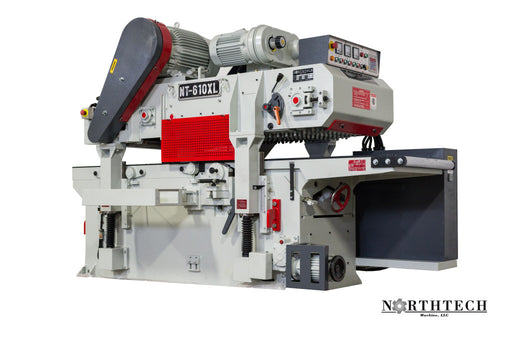

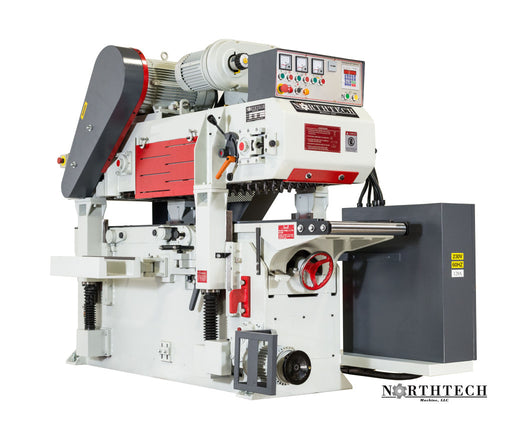

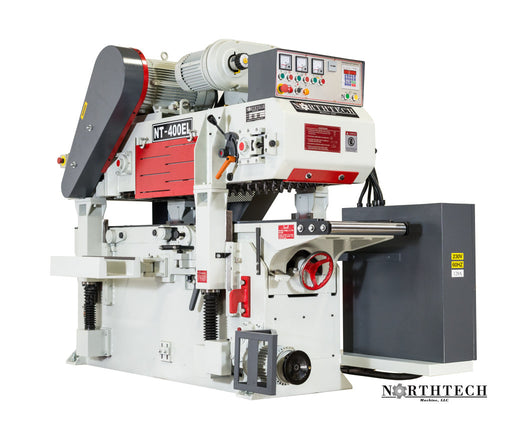

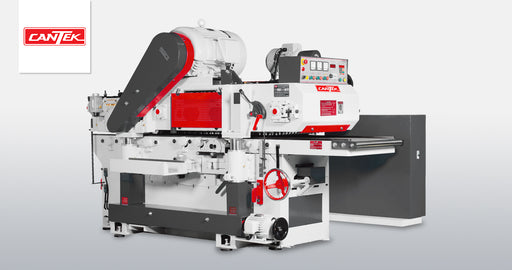

A double surface planer, a robust and essential woodworking machine, serves a crucial purpose in the woodworking industry by meticulously creating smooth and parallel surfaces on both sides of a workpiece. It accomplishes this by expertly passing the material through two horizontal cutter heads, each dedicated to the top and bottom surfaces, effectively removing excess material and providing uniform thickness. This precision in thicknessing is paramount for various woodworking projects, ensuring that the lumber or boards possess precisely surfaced and parallel attributes. Whether dimensioning rough lumber for construction or cabinetry, producing uniform thickness in floorboards for the flooring industry, or crafting furniture components with consistent dimensions, the double surface planer is a workhorse that guarantees meticulous results. Its role in optimizing woodworking efficiency and achieving material uniformity makes it an indispensable asset in the industry, enhancing the quality and appearance of the final products.

Key Features of Double Surface Planers:

Double surface planers offer a range of features for efficient woodworking:

- Dual Cutter Heads: These machines are equipped with two cutter heads, one for the top surface and one for the bottom, ensuring simultaneous and uniform thicknessing.

- Variable Thickness Settings: Adjustable settings allow for precise control of the material's thickness, accommodating various project requirements.

- Feed Systems: Efficient feed systems move workpieces smoothly through the machine, ensuring consistent results.

- Dust Collection: Integrated dust collection systems keep the workspace clean and reduce airborne particles.

Applications of Double Surface Planers:

Double surface planers are utilized in various woodworking applications, including:

- Dimensioning Lumber: These machines are instrumental in dimensioning rough lumber, producing precisely surfaced and parallel boards for construction and cabinetry.

- Flooring Production: In the flooring industry, double surface planers create uniform thickness in floorboards, enhancing the quality and appearance of the final product.

- Furniture Manufacturing: Manufacturers use these planers to achieve consistent thickness in furniture components, ensuring proper fit and quality.

Benefits of Using Double Surface Planers:

The advantages of incorporating double surface planers into woodworking operations are significant:

- Precision: These machines provide consistent, precise thicknessing, minimizing material waste and the need for additional finishing work.

- Time Efficiency: Double surface planers streamline the dimensioning process, reducing labor hours and production time.

- Quality Control: Woodworkers can achieve higher quality and uniformity in their products, enhancing the final appearance and performance.

Choosing the Right Double Surface Planer:

Selecting the appropriate double surface planer depends on specific project requirements:

- Material Size: Ensure the machine's capacity accommodates the dimensions of the materials you typically work with.

- Feed Speed: Evaluate the feed speed, as this impacts production efficiency.

- Adjustment Precision: Choose a model with accurate thickness adjustment mechanisms for precise control.

In conclusion, double surface planers are indispensable tools in the woodworking industry, ensuring precise and uniform thicknessing of materials. Understanding their key features, applications, benefits, and considerations for selecting the right model is essential for optimizing woodworking processes and achieving high-quality, dimensioned lumber and boards. Double surface planers are fundamental in various sectors, including construction, flooring, and furniture manufacturing, where precision and consistency are paramount in delivering exceptional products.