What Does a Miter Door Machine Do for Woodworking Manufacturers?

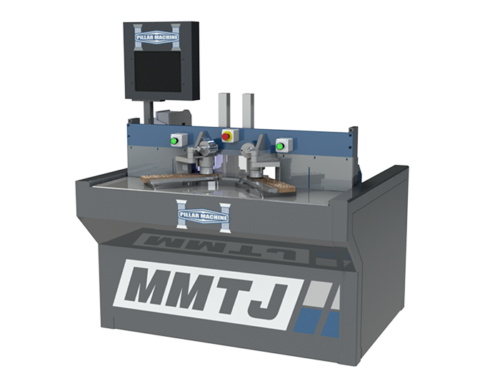

In the realm of woodworking and manufacturing, industrial miter door machines have become indispensable tools, especially for those involved in crafting high-quality cabinet doors and furniture. These specialized machines offer precise and efficient solutions for creating mitered doors, elevating the craftsmanship of woodworking manufacturers. So, what does a miter door machine do, and how does it benefit woodworkers at an industrial scale?

Key Features of Industrial Miter Door Machines:

Industrial miter door machines are equipped with a range of key features that set them apart:

- Precise Mitering: The primary function of a miter door machine is to create precise mitered edges on cabinet doors, ensuring tight joints and a clean, professional appearance.

- Variety of Cuts: These machines can perform a variety of cuts, including miter cuts, straight cuts, and cope cuts, allowing for versatility in door design.

- Speed and Efficiency: Miter door machines are known for their speed and efficiency, drastically reducing the time required for door assembly.

Applications of Industrial Miter Door Machines:

Miter door machines have a wide array of applications in the woodworking and manufacturing industries:

- Cabinet Door Manufacturing: Mitered cabinet doors are in high demand for their elegant aesthetics and craftsmanship. Miter door machines are essential for producing these doors efficiently and accurately.

- Furniture Production: Manufacturers crafting high-end furniture pieces often require mitered door panels to match the overall design. Miter door machines contribute to the creation of seamless, stylish doors.

- Architectural Millwork: These machines are used to create mitered door components for architectural millwork, such as custom moldings, wainscoting, and custom-built cabinetry.

Benefits of Using Industrial Miter Door Machines:

The advantages of incorporating industrial miter door machines into woodworking processes are significant:

- Precision and Quality: Miter door machines ensure that mitered door components fit perfectly, resulting in tight, professional joints and high-quality doors.

- Time Efficiency: These machines expedite the door-making process, reducing labor hours and production time, which is crucial for industrial-scale woodworking.

- Versatility: Miter door machines allow for diverse door designs, coping cuts, and customizations, catering to the unique needs of each project.

Choosing the Right Industrial Miter Door Machine:

Selecting the appropriate industrial miter door machine is essential for optimizing manufacturing operations. Consider factors such as:

- Size and Capacity: Ensure the machine's size and capacity align with the door sizes you commonly produce.

- Cutting Abilities: Choose a machine with the cutting options required for your specific projects, including miter, straight, and cope cuts.

- Automation Features: Some miter door machines offer advanced automation, improving efficiency and reducing manual labor.

Maintenance and Care of Industrial Miter Door Machines:

Regular maintenance is essential to keep industrial miter door machines in top working condition. Maintenance tasks may include cleaning, lubrication, and routine checks of mechanical components.

Price Range of Industrial Miter Door Machines:

The cost of industrial miter door machines varies based on their features, capacity, and automation capabilities. Entry-level machines may start at a few thousand dollars, while high-end, fully automated models can reach several hundred thousand dollars. Manufacturers should consider their specific needs and budget constraints when choosing a machine.