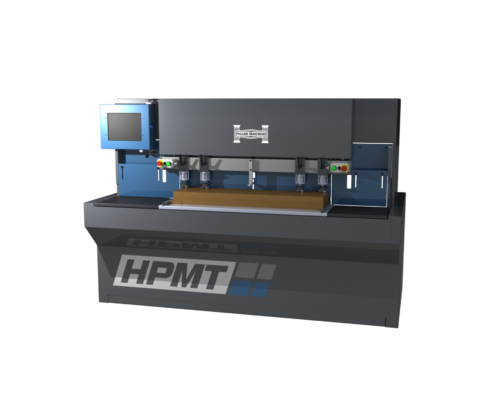

Pillar Machine | HPMT – Mortise and Tenon Machine

Original price

$50,000.00

-

Original price

$50,000.00

Original price

$50,000.00

$50,000.00

-

$50,000.00

Current price

$50,000.00

The HPMT has a working length of 48”. This machine has a full three axis CNC control. One spindle is used for the mortise work and a separate spindle is used for tenon work. Two working zones are used, allowing for left and right hand programs.

The HPMT performs the following functions:

- Mortising

- Tenoning

Standard Features:

- X, Y, Z CNC axis positioning

- 15″ Industrial color touchscreen for creating and selecting programs

- 48″ zone for rails and stiles – Left and Right hand fence

- 1″ tenon height (Standard)

- 3 HP high frequency 18,000 RPM direct drive routing spindle for mortising

- 6 HP high frequency 18,000 RPM direct drive routing spindle for tenoning

- Drop down rear fences for referencing

- 1″ thick machined aluminum work surface for reliable referencing

- Material thickness up to 2″ (Standard)

- Heavy duty 2800 lb. frame

Advantages of The HPMT:

- Elimination of complicated machine setup

- Provide a stronger product

- Easy assembly by providing self aligning joints

Options:

- Inside profiling HSK spindle

- Inside plow spindle

- Additional horizontal spindles

- Dowel insertion

- End Coping

- Louver grooving

- Hinge pocketing

- Additional Horizontal spindles (Pilot Drilling)

- Longer table lengths

- CNC control of rail length sizing

- Barcode reader

- Networking

- Offline programming

- Parametric programming (Standard or built to customer specification)