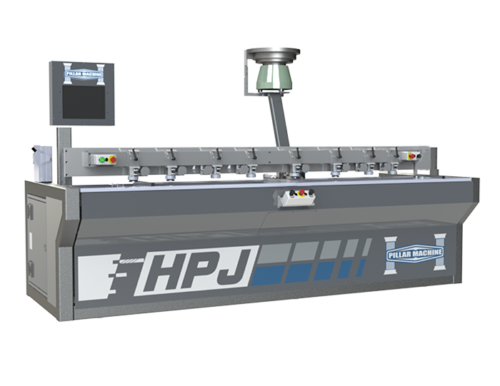

Pillar Machine | HPJ-96 – Horizontal Bore and Dowel

Original price

$50,000.00

-

Original price

$50,000.00

Original price

$50,000.00

$50,000.00

-

$50,000.00

Current price

$50,000.00

The HPJ 96 is a Horizontal Bore and Dowel insertion CNC machining center used for case construction in cabinet and/or furniture manufacturing, good for all of your horizontal boring needs.

The HPJ-96 performs the following functions:

- Horizontal Boring

- Glue Insertion

- Dowel Insertion

Standard Features:

- X Axis CNC control for positioning

- 15″ industrial color touchscreen for creating and selecting programs

- 2 zones

- 4 clamp units

- 3 HP high frequency 18,000 RPM direct drive routing spindle

- Digital mechanical readouts for height and depth

- 96″ work zone

- Heavy duty 3200 lb. frame

- 1″ thick machined aluminum work surface covered with a 3M maintenance free non-slip surface

- Our standard sealed glue injecting system injects glue or water with little to no maintenance.

- Small footprint to conserve floor space

- Our “protrusionator” dowel inserter allows for adjustment of dowel protrusion.

Advantages of The HPJ-96:

- Elimination of complicated machine setup

- Quick, accurate assembly

- Gain production times on CNC routers and Point to Points by shifting boring and doweling to the HPJ.

Options:

- Additional horizontal spindles (pilot drilling for confirmat screw)

- Vertical boring spindle

- Longer table lengths

- CNC control of additional axis

- Additional work zones

- Additional work zones dedicated for rail end work (for doweling face frames)

- Bar-code reader

- Offline programming

- Parametric programming (standard or built to customer specifications)

- Routing

- Louver grooving

- Dado rrouting

- “Modeez Clip” routing