Anderson | Andimaxx

CNC Routers( 3 & 4 Axis Series)

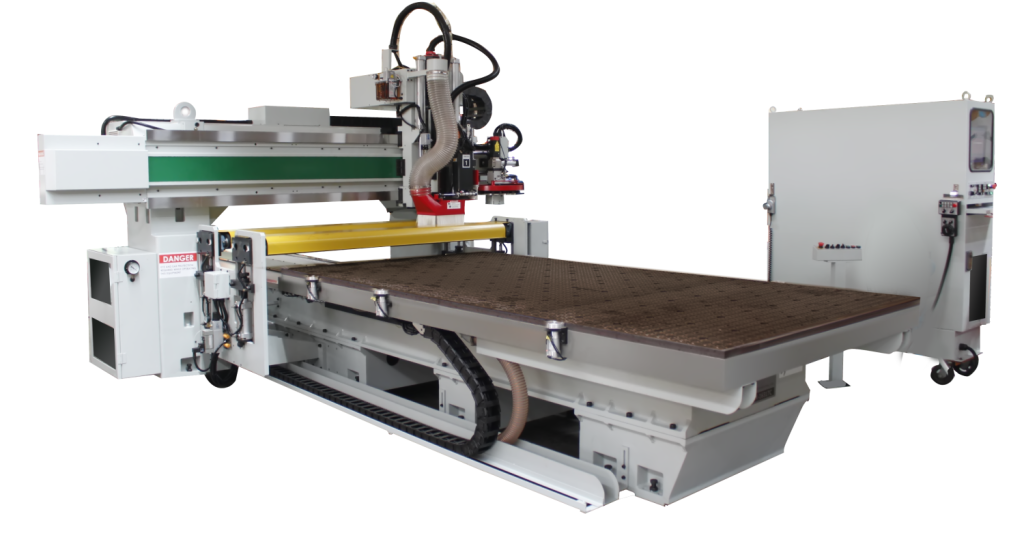

ANDIMAXX Series

The ANDIMAXX Series Moving Table 3-axis machining centers set a new level of CNC accuracy and machining performance. The combination of a highly rigid base, steel weldments and castings and high accuracy Servo System make the ANDIMAXX an ideal choice for machining wood, MDF, plywood plastic, aluminum and composite materials.

The Anderson fixed bridge and moving table design provides easy machine access. The webbed steel substructure remains smooth and rigid while cutting in X, Y and Z-axis. The ANDIMAXX CNC machining centers set a new standard in high speed CNC machining and as it is designed to handle heavy duty CNC machining in thin and thicker flat and aluminum plate. The ANDIMAXX CNC machining center is designed to handle heavy duty CNC machining in thin and thicker flat and autoclaved composites. CNC Controls include Ethernet options to provide remote technical support; optional C-Axis is available. Work piece holding flexibility is provided by optional clamping, grid or manifold vacuum systems. The ANDIMAXX CNC Machining Center utilizes an industry standard G-code for control functions that allows easy interfacing with all major CAD/CAM software and industry standard solid modeling software packages.

Features

TC

Standard spindle configuration is a 15 HP Air cooled dynamic (travels with spindle) router spindle 0-24,000 rpm. 10, 12 or 16-position automatic tool changers are options. Robotic Arm Tool Changer and Water Cooled spindle versions are available. Single and Twin spindles option available.

TC+D

Standard boring unit is a 5 x 5 vertical spindle unit with horizontal boring unit with slotting saw option.

TC2

Open Architecture ANDI-Fanuc control with PC front-end processes industry standard code via a standalone Windows PC or Network PC enabling users to work with virtually any CAD/CAM or 3rd party software supplier.

Specifications

| Basic configuration | ANDIMAXX |

|---|---|

| Standard Controller | FANUC Oi |

| HP | 18 / 24 / Vector |

| Taper/Cone | HSK-63F |

| Max RPM | 24.000 rpm |

| Cooling(std) | air-cooled |

| Optional Cooling | water-cooled |

| Ride Along Toolchanger | 10/ 12 |

| Type | Dynamic (moves with Spindle) |

| Table Size | 5 x 8 5 x 10 5 x 12 6 x 8 6 x 10 6 x 12 |

| No. of Vacuum Zones | 1 |

| Part Locating Pop-Up Pins | 8 |

| Table top part material | Hi-Pressure phenolic-grid |

| Table base | Steel Construction |

| Optional Vacuum Pumps(HP) | 10 / 25 / 40 / 50 HP |

| Auto Tool Length Setter | inclusive |

| Manual Jog Control(MPG) | inclusive |

| Aluminum Table Top in lieu of Phenolic top | optional |

| Bar code reader | optional |

| C-axis | optional |

| Reverse Air Flow for Vacuum Table | optional |

| Mister for Cutting Tools | optional |

| Boring Block | 5+5, 10+7, 20+20 |

| Additional Tool Storage | 16, 20 ,32 tools |