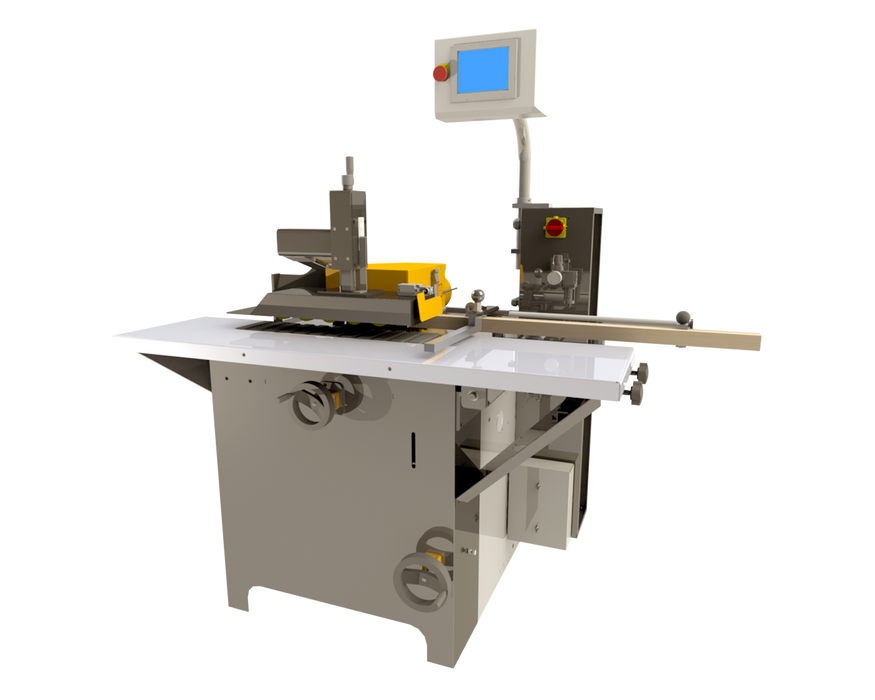

Pillar Machine | LARICK 390 Automatic Shaper

The Model 390 Automatic Shaper is a different concept in shapers. This shaper is conveyor fed, making it ideal for shaping small parts which could not be fed with a conventional power feeder.

This 7 1/2 HP inverter controlled variable speed shaper can shape pre-arched panels automatically. Using a template, it can also hog out arched panels. Horizontal and vertical shaper adjustments with digital position indicators and the 5 position fence make profile changeovers extremely quick and simple. The 390 features tried and proven technology from Larick’s 410 Shaper/Sander – the 6 inch wide conveyor with staggered hold down tires, floating head shaper, and 5 position chipbreaker fence.

This versatile shaper with its fast and easy changeover makes it ideal for the shop with a large inventory of profiles.

390 Automatic Shaper

The 390 Automatic Shaper is an unrivaled type of shaper. Applications include making every part for arched raised panel doors in small cabinet shops to being dedicated to one profile in larger factories.

The “HANDS-OFF” method of arching panels and rails is safe and non-intimidating. The ability to “climb cut” drastically reduces reject parts, especially on arched rails. The feed rate can “follow” the shaper load, slowing down and speeding up as the cutter’s load varies.

Digital counters show the shaper’s horizontal and vertical position, and the fence has five adjustable stop positions. Therefore, changing tooling normally takes only about two minutes because all settings can be pre-set. As a result, a small shop making two to three tooling changes per day can usually save an hour of setup time each day which will more than pay for the cost of the machine.

Unlike arch door making systems using hand held fixtures, we placed a centering jig with a template over the part and fed them through the machine. The hold-down tires clamp the jig and part together on the conveyor. A bearing on the spindle contacts the template and pushes the shaper spindle back. The result is that the spindle moves back and forward and follows the template while the part is fed through. Climb cutting is possible with this system which almost eliminates rails splitting and chipping, reducing scrapped parts.

Machine Specifications

- SHAPER MOTOR: 7 1/2 HP 208-230V 3PH

- SHAPER SPEED: 4000 to 7000 RPM

- SPINDLE SIZE: 1 1/4 INCH

- FEED SPEED: VARIABLE TO 30 FPM

- CONVEYOR: 6 INCH WIDE

- MAX PART THICKNESS: 2 INCH

- FLOOR SPACE: 55” WIDE, 38” DEEP