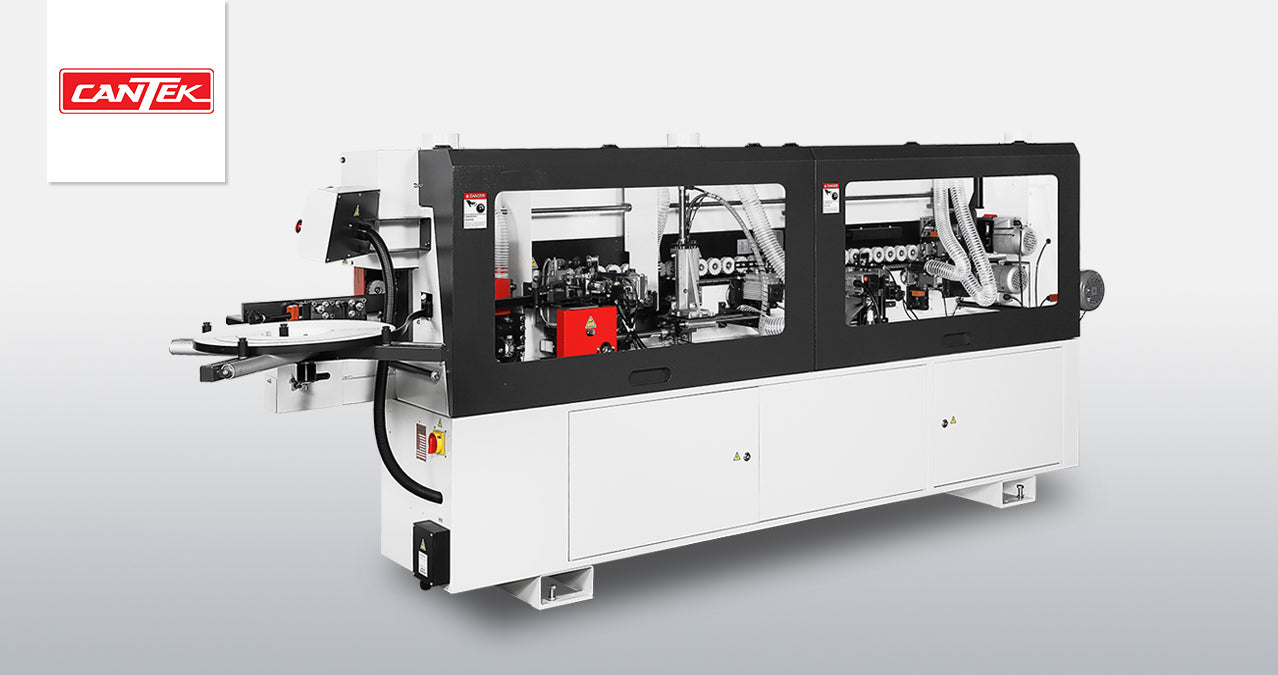

CANTEK | MX370PW Automatic Edgebander

From cabinet parts to cabinet doors, this edgebander can do it all.

The Cantek MX370PW Edgebander with Premilling and Corner Rounding is designed to be a compact and durable edgebander offered at an affordable price. This machine is equipped with premilling, end trimming, flush trimming, corner rounding, PVC scraping, and buffing. User-friendly controls and adjustments allow for efficient changeovers of edge tape thicknesses between 0.4mm & 3mm. It comes equipped with a strip feed magazine for automatically feeding of strips including wood, laminate etc.

Why Cantek MX370PW Edgebander?

- Automatic strip feed magazine with up to 6mm edge capacity

- Versatile edgebander capable of applying 0.4mm to 3mm edge tape.

- Quick change glue pot allows you to change glue colours in minutes.

- Premilling ensures a perfectly square edge and clean panel to work with, resulting in a minimally visible glue joint.

- The corner rounding function finishes the ends of cabinet doors with a radius edge, eliminating any manual rework of the panel.

Key Advantages

- Automatic edge feeding with a thickness capacity of 0.4–3 mm

- Conveyor chain feed system for reliable results.

- Teflon-coated hot-melt glue pot.

- Heated infeed fence for pre-heating the panel for optimum glue penetration.

- PLC control system with LED display and keypad.

- Workpiece is fed by chain.

- Edge coil support plate: Ø 800mm (31 ½”) for PVC/ABS.

- Spring-loaded pressure unit with (2) pressure rollers.

- Heavy-duty pressure beam with extendable workpiece support.

Working Units

PREMILLING UNIT

High-frequency pre-milling units can remove up to 3mm and are designed to provide an ideal edge for applying edge tape by cleaning up poorly cut panels.

(2) counter-rotating diamond cutterheads for optimum results and longevity.

END TRIM

High frequency 12000 RPM end trimming unit, with Ø100mm (4”) TC-Saw blades.

TOP & BOTTOM TRIM

High frequency 12000 RPM top & bottom trimmers with insert knife cutters for radius trimming & bevel trimming.

CORNER ROUNDING

High-frequency corner rounding unit can process 0.4-3mm thick edgebanding by tracing the shape of the panel.

RADIUS SCRAPING

Radius scraper with 2mm radius.

BUFFING

3000 RPM top & bottom buffing units to polish the machined edge.

Specifications

Feeding speed | 29 FPM | 9 meters/min. |

Panel thickness | 0.315″ ~2.36″ (coil)0.315”~2” (strip) | 8~60 mm (coil)8~50mm (strip) |

Edge thickness – coil | 0.0158”~0.118” | 0.4 ~ 3 mm |

Edge thickness – strips | to 0.24” | to 6 mm |

Min. panel width | 3 ¾” | 95 mm |

Min. panel length | 6.7″ | 170 mm |

Working table height | 38″ | 960 mm |

Extension support width | 22″ | 560 mm |

Dust collection outlet | Ø 5″ x3 | Ø 127 mm x3 |

Air consumption | 12.36 CFM | 350 liters/min |

Electrical consumption | 10.9 HP | 6.7 KW |

Electrical requirement | 230/3/60 | 26 Full load amps |

Machine weight | 2160 lbs | 980 kgs |

Machine dimensions | 156” x 29” x 69” | 3960 x 730 x 1748mm |

MOTOR SPECIFICATIONS

Feeding motor | 0.75 kW |

Pre-milling motors (2 pcs) | 1.5 kW |

Glue spindle motor | 0.25 kW |

Front/rear trimming motor | 0.37 kW (12000 RPM) |

Upper trimming motor | 0.37 kW (12000 RPM) |

Lower trimming motor | 0.37 kW (12000 RPM) |

Corner rounding motor | 0.35 kW (12000 RPM) |

Upper buffing motor | 0.12 kW (3000 RPM) |

Lower buffing motor | 0.12 kW (3000 RPM) |

Pre-heating | 0.125 kW |

Gluepot | 1.315 kW |