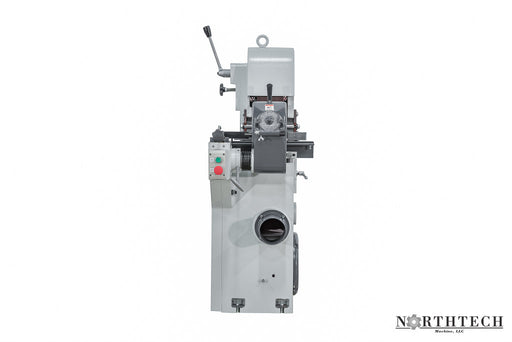

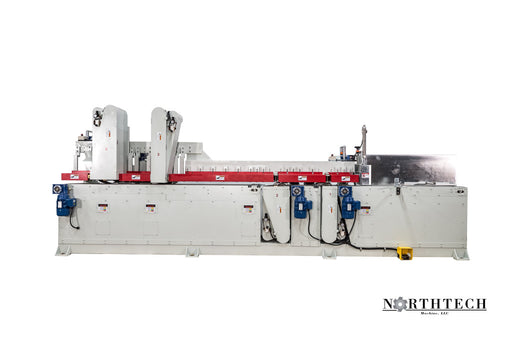

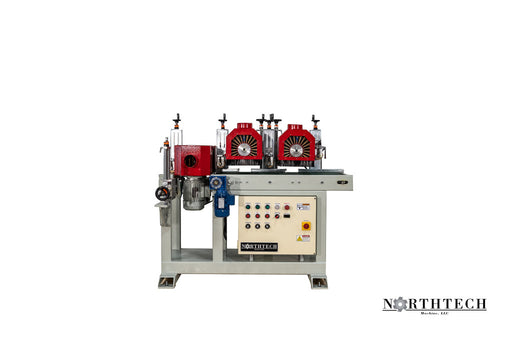

A sander is a woodworking machine designed to smooth and finish wood surfaces by removing material through abrasion. Sanders come in various types, including belt sanders, disc sanders, drum sanders, and random orbital sanders, each suited for different applications and finishes. Sanders are essential for preparing surfaces for staining, painting, or sealing, as well as for removing imperfections and achieving a smooth, uniform appearance.

Key Features of a Sander

Multiple Sanding Surfaces: Sanders may feature different sanding surfaces such as belts, discs, drums, or pads, offering versatility for various sanding tasks.

Variable Speed Control: Many sanders come with variable speed control, allowing for flexibility in sanding different materials and achieving desired finishes.

Dust Collection System: Integrated dust collection systems help keep the workspace clean and reduce airborne particles for improved safety and visibility.

Ergonomic Design: Sanders often feature ergonomic designs with comfortable handles and controls for ease of use and reduced operator fatigue.

Adjustable Sanding Depth: Some sanders offer adjustable sanding depth or pressure settings for controlling the amount of material removed and achieving precise results.

Applications of a Sander

Surface Preparation: Sanders are used to prepare wood surfaces for finishing by removing old finishes, smoothing rough surfaces, and leveling uneven areas.

Stock Removal: Sanders can quickly and efficiently remove excess material from workpieces, such as rough-sawn lumber or glued-up panels.

Final Finishing: Sanders are essential for achieving smooth and uniform finishes on furniture, cabinetry, flooring, and other woodworking projects.

Deburring and Polishing: Some sanders are used for deburring metal edges or polishing surfaces to a high sheen.

Choosing the Right Sander

Type of Sander: Consider the type of sander (belt, disc, drum, orbital) based on your specific sanding tasks and the type of material you'll be working with.

Sanding Capacity: Evaluate the sanding capacity of the sander to ensure it can handle the size and thickness of your workpieces.

Variable Speed: Choose a sander with variable speed control for versatility in sanding different materials and achieving desired finishes.

Dust Collection: Look for a sander with an effective dust collection system to maintain a clean and safe working environment.