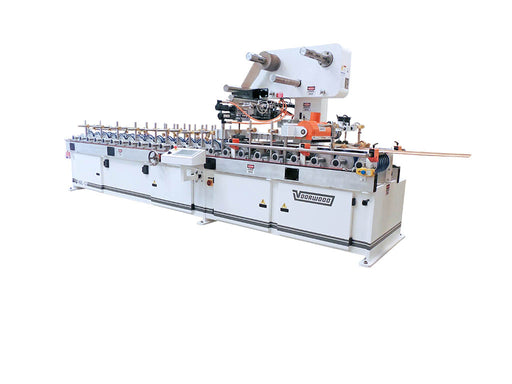

A profile wrapper, also known as a profile laminator, is a specialized machine used in the woodworking industry to apply decorative laminates or veneers onto profiled surfaces of wood components. Its primary function is to wrap or laminate profiles, such as edges, moldings, or trim pieces, with thin sheets of laminate material, enhancing their aesthetic appeal and durability.

Key Features of a Profile Wrapper

Adjustable Heating System: Profile wrappers feature adjustable heating elements or infrared lamps to activate the adhesive on the laminate material, ensuring proper bonding to the wood surface.

Pressure Rollers: Many machines are equipped with pressure rollers or belts to apply consistent pressure on the laminate material, ensuring smooth adhesion and eliminating air bubbles or wrinkles.

Profile Compatibility: Profile wrappers come with adjustable guides, rollers, or conveyor systems to accommodate various profile shapes, sizes, and thicknesses, allowing for precise wrapping of curved or irregular surfaces.

Adhesive Application System: Some machines feature adhesive application systems, such as hot melt glue pots or spray systems, to apply adhesive evenly onto the profiled surface before laminating, ensuring strong and reliable bonds.

Integrated Trimming Mechanism: Certain models come with integrated trimming units or cutters to trim excess laminate material from the edges of the wrapped profiles, resulting in clean and precise finished edges.

Applications of Profile Wrappers

Furniture Manufacturing: Profile wrappers are commonly used in furniture manufacturing for wrapping edges, moldings, and trim pieces with decorative laminates or veneers, enhancing the appearance and durability of furniture components.

Architectural Millwork: Woodworkers utilize profile wrappers to laminate architectural moldings, casings, and trim profiles with decorative finishes, providing custom solutions for interior and exterior applications.

Door and Window Production: Profile wrappers are employed in door and window production to laminate door edges, window frames, and sash profiles with durable and weather-resistant laminate materials for enhanced aesthetics and performance.

Store Fixtures and Displays: Profile wrappers are used in the production of store fixtures, displays, and point-of-sale materials to apply decorative laminates or veneers onto profiled surfaces, creating attractive and durable retail environments.

Choosing the Right Profile Wrapper

Profile Size and Complexity: Consider the size and complexity of the profiles you intend to wrap and ensure the machine can accommodate the dimensions, shapes, and curvature of your workpieces.

Heating and Pressure Control: Look for a profile wrapper with adjustable heating and pressure control features to accommodate different laminate materials and ensure proper bonding and adhesion.

Adhesive Application Method: Evaluate the adhesive application method of the machine, such as hot melt glue or spray adhesive, to ensure compatibility with your laminate materials and production requirements.

Trimming and Finishing Options: Choose a machine with integrated trimming units or finishing options to achieve clean and precise edges on the wrapped profiles, minimizing post-processing and enhancing overall efficiency.