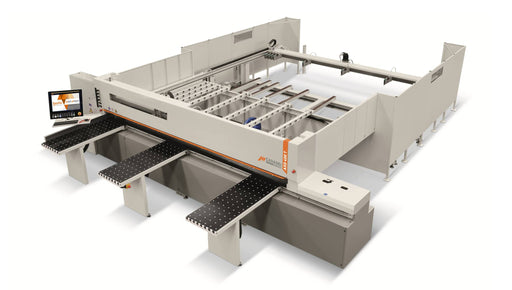

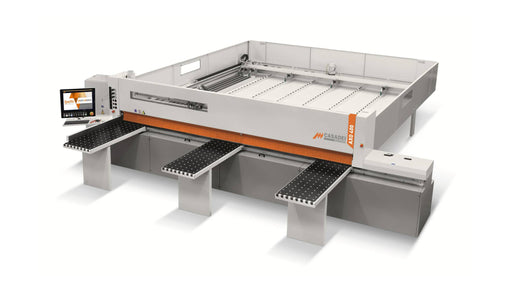

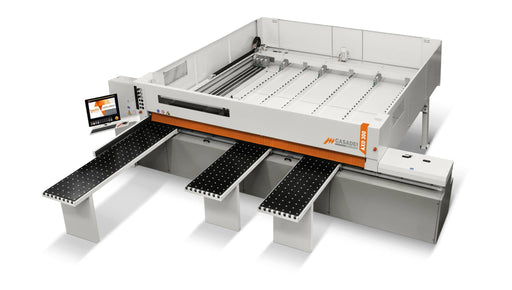

A panel saw is a woodworking machine used to cut large sheets of material, such as plywood, MDF, or particleboard, into smaller, more manageable pieces. Its primary function is to make straight, precise cuts across the length or width of a panel, allowing woodworkers to quickly and accurately break down large sheets into smaller components for further processing or assembly.

Key Features of a Panel Saw

Sliding Table: Panel saws feature a sliding table or carriage that supports the workpiece and allows it to move smoothly past the cutting blade, ensuring accurate cuts across the entire length of the panel.

Vertical Cutting Capacity: Many panel saws offer vertical cutting capabilities, allowing users to make rip cuts along the length of the panel or cross cuts across the width, depending on the orientation of the blade.

Scoring Blade: Some panel saws come equipped with a scoring blade in addition to the main cutting blade, which helps prevent tear-out and chipping on the surface of the panel, especially when cutting laminated materials.

Adjustable Cutting Depth and Angle: Panel saws typically offer adjustable cutting depth and angle settings, allowing users to make bevel cuts or dado cuts for joinery or decorative purposes.

Dust Collection System: Many modern panel saws feature integrated dust collection systems or ports to capture sawdust and debris generated during cutting, maintaining a clean and safe working environment.

Applications of Panel Saws

Cabinetmaking: Panel saws are essential for cutting large sheets of plywood or MDF into smaller panels for building cabinets, shelving units, and other furniture pieces.

Millwork and Joinery: Woodworkers use panel saws to accurately size and shape panels for creating doors, windows, moldings, and other architectural millwork components.

Sign Making and Display Fabrication: Panel saws are utilized in sign shops and display fabrication shops to cut panels of acrylic, PVC, or aluminum composite material for signage, exhibits, and displays.

Woodworking Production: Panel saws are employed in woodworking production facilities to streamline the cutting process for batch production of standardized components, such as drawer boxes, cabinet doors, and furniture parts.

Choosing the Right Panel Saw

Cutting Capacity: Consider the cutting capacity of the panel saw, including maximum cutting width and depth, to ensure it can handle the size of the panels you typically work with.

Accuracy and Precision: Look for a panel saw with features such as precision guides, adjustable stops, and digital readouts to achieve accurate and repeatable cuts for your woodworking projects.

Scoring Blade: Evaluate whether a panel saw with a scoring blade is necessary for cutting laminated materials or veneered panels without tear-out or chipping.

Space and Mobility: Consider the footprint of the panel saw and whether it can be easily moved or relocated within your workshop space to accommodate workflow and production needs.