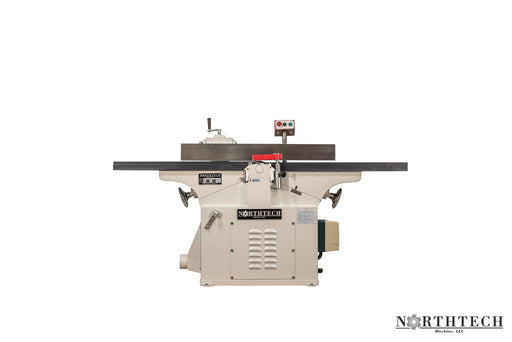

A jointer machine, also known as a surface planer, is a critical tool in industrial woodworking. Its primary function is to create flat and smooth surfaces on the faces and edges of rough or irregularly shaped boards. It accomplishes this by removing excess material from the workpiece with a rapidly rotating cutter head. The result is a straight, flat, and perfectly square surface that serves as the reference point for subsequent woodworking processes. Jointers are instrumental in preparing wood for further operations like edge-gluing, ensuring that the joined pieces fit perfectly and creating finished surfaces ready for additional detailing.

Key Features of Jointer Machines:

Jointer machines offer several features to enhance their functionality:

- Adjustable Cutting Depth: Jointers typically allow for precise depth adjustments, enabling control over the amount of material removed.

- Long Bed: A long bed or table provides support for the workpiece, allowing for the jointing of longer boards.

- Fence System: An adjustable fence system ensures that the workpiece is held securely and that the material is cut at a precise angle.

- Dust Collection: Integrated dust collection systems help keep the workspace clean and reduce airborne particles.

Applications of Jointer Machines:

Jointer machines find applications in various woodworking tasks, including:

- Preparing Lumber: Jointers are crucial for preparing rough-sawn lumber for further processing, ensuring flat and square edges and faces.

- Edge Jointing: They are used for creating straight and flat edges on boards, which is essential for producing panels and tabletops.

- Edge-Gluing: Jointers play a role in preparing edges for edge-gluing operations, ensuring a perfect bond between pieces.

Benefits of Using Jointer Machines:

The advantages of incorporating jointer machines into woodworking operations are significant:

- Flatness and Precision: Jointers create flat and perfectly square surfaces, ensuring that joined pieces fit seamlessly.

- Improved Efficiency: They expedite the preparation process, reducing manual effort and saving time.

- Enhanced Quality: Jointers enhance the quality and aesthetics of woodworking projects by providing finished surfaces ready for further detailing.

Choosing the Right Jointer Machine:

Selecting the appropriate jointer machine depends on specific project requirements:

- Cutting Width: Consider the width of the boards you typically work with and choose a jointer machine that accommodates those dimensions.

- Bed Length: Evaluate the bed length or table size to ensure it suits the length of your workpieces.

- Adjustability: Look for models with precise depth and angle adjustments for versatility in different woodworking tasks.

- Dust Collection: Machines with effective dust collection systems contribute to a cleaner and safer workspace.

In conclusion, jointer machines for industrial woodworking are essential tools for creating flat, square, and smooth surfaces on rough or irregularly shaped boards. Understanding their key features, applications, benefits, and considerations for selecting the right model is crucial for optimizing woodworking processes and achieving high-quality results. Jointers are indispensable assets in the woodworking industry, ensuring that materials are prepared to the highest standards, ready for further crafting and detailing.