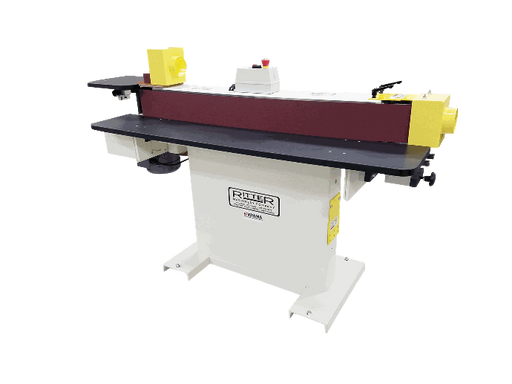

A horizontal edge belt sander is a woodworking machine used for sanding and shaping the edges of wood pieces. Its primary function is to remove material from the edges of workpieces using a continuous abrasive belt rotating around horizontal rollers. Horizontal edge belt sanders are commonly used in woodworking shops and manufacturing facilities to refine the edges of boards, panels, and other wood components, achieving smooth and uniform surfaces.

Key Features of a Horizontal Edge Belt Sander

Horizontal Belt Orientation: Horizontal edge belt sanders feature a horizontal belt orientation, allowing for easy access and precise sanding of workpiece edges.

Adjustable Belt Speed: Many sanders offer adjustable belt speed settings to accommodate different types of wood and sanding applications, allowing for optimal material removal and surface finish.

Adjustable Table Angle: Some sanders come with adjustable table angles or tilting mechanisms, enabling users to sand beveled edges or chamfers with precision and control.

Dust Collection System: Edge belt sanders are equipped with dust collection systems or ports to capture sanding dust and debris, maintaining a clean and safe work environment.

Variable Pressure Control: Certain models feature variable pressure control systems to adjust the pressure applied to the sanding belt, allowing for consistent results on different wood species and grain patterns.

Applications of a Horizontal Edge Belt Sander

Edge Finishing: Horizontal edge belt sanders are used to refine and smooth the edges of wood boards, panels, and components, preparing them for further finishing or assembly.

Beveling and Chamfering: Edge belt sanders can be used to create beveled edges or chamfers on wood pieces, adding decorative accents or easing sharp edges for safety.

Deburring and Smoothing: Sanding machines are employed for deburring and smoothing the edges of metal or composite materials, removing burrs, sharp edges, or imperfections.

Shape Sanding: Horizontal edge belt sanders are utilized for shaping curved or contoured edges on wood components, allowing for precise and uniform shaping of profiles or contours.

Choosing the Right Horizontal Edge Belt Sander

Belt Size and Configuration: Consider the size and configuration of the sanding belt, including width and grit, to ensure compatibility with your specific sanding requirements and workpiece dimensions.

Adjustability and Versatility: Look for a sander with adjustable settings for belt speed, table angle, and pressure control to accommodate a wide range of sanding applications and wood types.

Dust Collection Efficiency: Evaluate the effectiveness of the dust collection system in capturing sanding dust and debris, ensuring a clean and safe working environment.

Build Quality and Durability: Choose a horizontal edge belt sander constructed from robust materials with reliable components and features for long-term durability and performance.