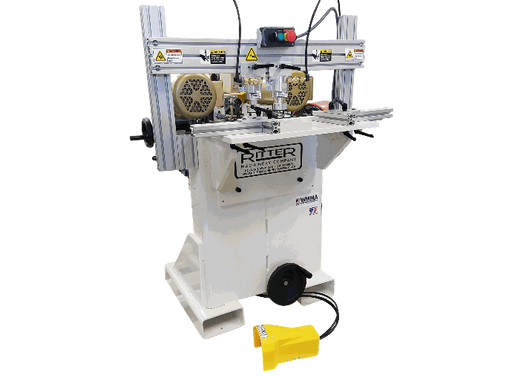

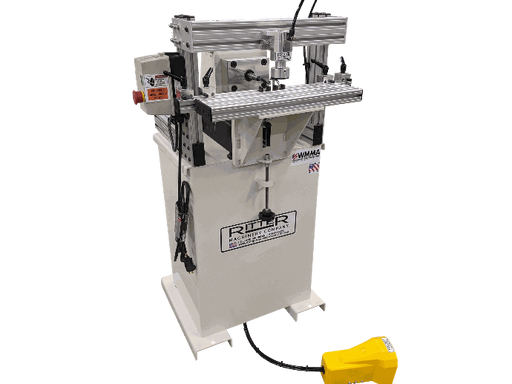

A horizontal boring machine, also known as a horizontal boring mill, is a specialized machining tool used to create precise holes or bores in large workpieces. Its primary function is to bore holes horizontally into the workpiece, typically using a single-point cutting tool or drill bit. Horizontal boring machines are commonly used in industries such as manufacturing, aerospace, and automotive for machining engine blocks, gearboxes, and other large components with precision and accuracy.

Key Features of a Horizontal Boring Machine

Horizontal Spindle: Horizontal boring machines feature a horizontal spindle orientation, allowing for horizontal drilling or milling operations on large workpieces.

Adjustable Worktable: Many horizontal boring machines come with adjustable worktables or beds to accommodate different workpiece sizes and configurations.

Multiple Axes: Horizontal boring machines may have multiple axes of movement, including X, Y, and Z axes, for precise positioning and drilling of holes at various angles and depths.

Spindle Speed Control: Boring machines offer spindle speed control features to adjust the rotational speed of the cutting tool or drill bit based on the material being machined and the desired hole diameter.

Automatic Tool Changer: Some horizontal boring machines are equipped with automatic tool changers that allow for quick and easy exchange of cutting tools or drill bits, reducing downtime and increasing productivity.

Applications of a Horizontal Boring Machine

Large Component Machining: Horizontal boring machines are used for machining large and heavy workpieces such as engine blocks, cylinder heads, and gearbox housings in industries like automotive and heavy machinery manufacturing.

Complex Hole Drilling: Horizontal boring machines are capable of drilling precise and complex holes, bores, and profiles in components requiring tight tolerances and intricate geometries.

Production of Jigs and Fixtures: Horizontal boring machines are employed in the production of jigs, fixtures, and tooling components used in manufacturing processes to ensure accuracy and repeatability.

Custom Machining Projects: Horizontal boring machines are utilized for custom machining projects in industries such as aerospace, defense, and marine engineering to fabricate specialized components and assemblies.

Choosing the Right Horizontal Boring Machine

Size and Capacity: Consider the size and capacity of the horizontal boring machine to ensure it can accommodate the size and weight of your workpieces.

Accuracy and Precision: Look for a horizontal boring machine with features such as precision ground ways, backlash compensation, and digital readouts to achieve accurate and repeatable machining results.

Automation and Integration: Evaluate the level of automation and integration capabilities of the boring machine with other machining systems or production processes to optimize workflow efficiency.

Tooling and Accessories: Choose a horizontal boring machine that offers a wide range of tooling options, accessories, and customization features to meet your specific machining requirements and preferences.