A dust collector is an essential machine in woodworking and other industries that generates dust and debris during the manufacturing process. Its primary function is to capture and remove airborne particles from the workspace, ensuring a cleaner and safer environment for workers. Dust collectors use various methods such as filtration, cyclonic action, or electrostatic precipitation to trap dust and prevent it from circulating in the air.

Key Features of Dust Collectors

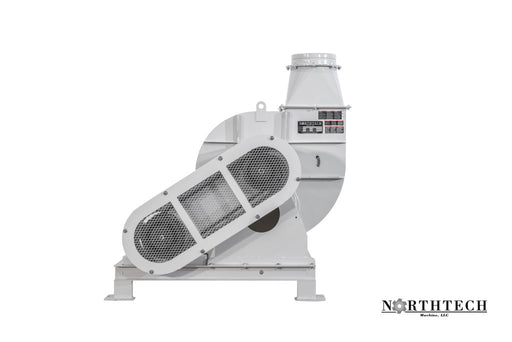

High Airflow Capacity: Dust collectors feature powerful motors and high airflow rates to effectively capture and remove dust particles from the air.

Filtration System: Many dust collectors come with efficient filtration systems, including filters with different micron ratings to capture particles of varying sizes.

Dust Collection Bags or Bins: Dust collectors collect dust and debris in bags or bins, which can be easily emptied and replaced when full.

Automatic Cleaning Mechanisms: Some dust collectors feature automatic cleaning mechanisms such as filter shakers or pulse jet systems to maintain optimal airflow and filtration efficiency.

Portability and Mobility: Portable dust collectors with wheels or handles offer flexibility for moving the unit to different workstations or job sites.

Applications of Dust Collectors

Woodworking: Dust collectors are essential in woodworking shops to capture sawdust, wood chips, and other airborne particles generated by sawing, sanding, and routing operations.

Metalworking: In metalworking applications, dust collectors capture metal shavings, grinding dust, and other particulates produced during cutting, grinding, and finishing processes.

Plastics and Composites: Dust collectors are used in the plastics and composites industry to capture dust and fumes generated by molding, extrusion, and machining operations.

Food Processing: Dust collectors help maintain cleanliness and hygiene in food processing facilities by capturing airborne contaminants such as flour dust, spices, and food particles.

Choosing the Right Dust Collector

Airflow Capacity: Consider the airflow capacity of the dust collector to ensure it can effectively capture dust and debris generated by your specific applications.

Filtration Efficiency: Look for a dust collector with efficient filtration systems to trap fine particles and prevent them from re-entering the workspace.

Portability: If mobility is important, choose a dust collector with wheels or handles for easy transportation between work areas.

Noise Level: Evaluate the noise level of the dust collector to ensure it meets your comfort and safety requirements, especially in enclosed workspaces.