A bandsaw machine is a versatile and indispensable tool in the world of woodworking and metalworking. It operates with a continuous loop of a sharp-edged, toothed metal blade that moves around two wheels, allowing for precision cutting of various materials. Bandsaws excel at making straight cuts, curved cuts, and intricate shapes, making them ideal for a wide range of applications. In woodworking, they're used for resawing, cutting veneers, and crafting curved or irregular shapes. In metalworking, bandsaws are essential for cutting metal bars, pipes, and other profiles with accuracy. Their adaptability in handling diverse materials and cutting tasks makes them a must-have in any workshop, from small-scale DIY enthusiasts to large manufacturing facilities.

Bandsaw vs. Band Resaw: Understanding the Difference

Bandsaw:

A bandsaw is a versatile cutting tool that features a continuous loop of a sharp-edged, toothed metal blade. It's designed for making a wide variety of cuts in materials such as wood, metal, and plastic. Bandsaws excel at cutting curves, straight lines, and intricate shapes. They are commonly used in woodworking for tasks like resawing, cutting veneers, and shaping irregular or curved pieces. Bandsaws come in various sizes and configurations, making them adaptable to different applications and workspaces.

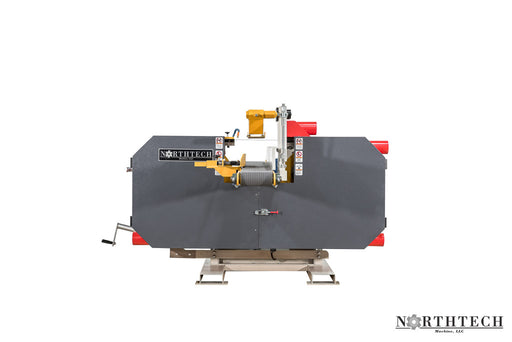

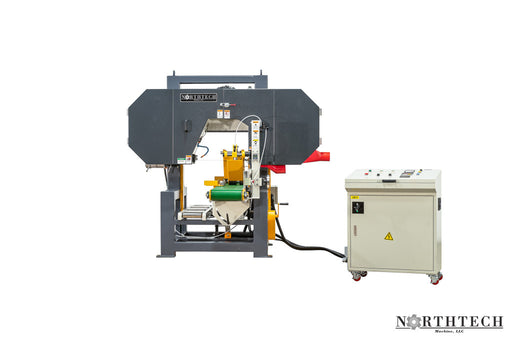

Band Resaw:

A band resaw is a specialized type of bandsaw, primarily designed for the specific task of resawing lumber. Resawing involves cutting a thick board into thinner boards or veneers. Band resaws typically have a larger throat depth and more robust construction to handle the demands of resawing wide and thick boards effectively. They are often used in sawmills and woodworking shops to maximize the yield from valuable lumber by producing multiple boards or veneers from a single, larger piece.

Key Features of Bandsaw Machines:

Bandsaws offer a host of features to enhance their functionality:

- Blade Guides: Adjustable blade guides ensure the blade stays in alignment during cutting.

- Variable Speed Control: Many models come with variable speed options for versatility in cutting different materials.

- Table Tilt: The ability to tilt the table allows for cutting bevels and angles.

- Resaw Capacity: Some bandsaws are designed with larger throat depths to accommodate resawing of wide boards.

Applications of Bandsaw Machines:

Bandsaw machines find applications in woodworking, metalworking, and other industries:

- Woodworking: Bandsaws are used for resawing lumber, shaping curves, cutting tenons, and more.

- Metalworking: In metal shops, bandsaws are vital for cutting various metal profiles and materials.

- Meat Processing: Bandsaws are also used in meat processing to cut meat into desired portions.

Benefits of Using Bandsaws:

The advantages of incorporating bandsaws into workshop operations are substantial:

- Precision: Bandsaws are known for their precise cuts, allowing for intricate and accurate work.

- Versatility: They can cut a wide range of materials, making them adaptable to different tasks.

- Efficiency: Bandsaws can make straight and curved cuts more efficiently than some other cutting tools.

- Safety: They are generally considered safer than some alternatives due to their enclosed blade.

Choosing the Right Bandsaw:

Selecting the appropriate bandsaw depends on specific project requirements:

- Throat Depth: Consider the throat depth or resaw capacity, which determines the size of materials the machine can handle.

- Blade Type and Size: Evaluate the blade type and size to match it with the materials you plan to cut.

- Variable Speed: Models with variable speed controls offer versatility for cutting various materials.

- Table Tilt: Choose a bandsaw with a tilting table if you require the ability to make angled cuts.

In conclusion, bandsaw machines are versatile and essential tools in the woodworking and metalworking industries, providing precision and adaptability in cutting a wide range of materials and shapes. Understanding their key features, applications, benefits, and considerations for selecting the right model is crucial for optimizing workshop processes and achieving high-quality results. Bandsaws are a cornerstone in the quest for excellence in woodworking, metalworking, and beyond.